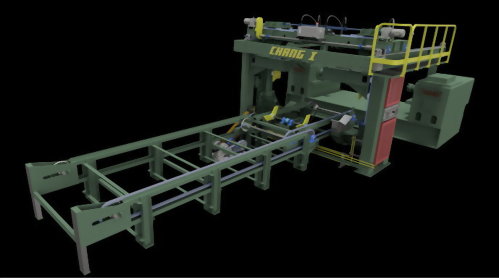

自動中板拼板機

全自動中板拼板機

全自動中板拼板機,全機拼接驅動採伺服馬達系統,控制為PLC系統操作。包含進料、板面缺陷破洞檢測、厚度檢測、廢料排除、定尺寸剪切,經由一位操作員進行操作工作。工作厚度最薄為0.9mm到最厚4.5mm。定尺所需加工尺寸後再輸送到自動收板架堆疊收料。

使用該機進行的單中板經由電子進行拼接,接縫位置精準牢固密合,防止板面乾裂。使用高強度工業絲線與熱熔膠,可在單中板切割之前用於輔助拼接,強化加工板面。

拼板機的輸送速度從22米至36米 / 每分鐘。(可調整) 與傳統的拼板機相比,可靈活調整並增加產量。定尺剪切和廢料計數由精密旋轉編碼器和高速計數器控制,以便在不浪費核心單板的情況下修剪最少的廢料。 最小剪裁寬度為75mm。

操作系統由PLC系統控制,操作更加簡便。同步的拼接系統,這使得加工拼板過程非常精確,以防止板重疊或離縫產生

新型設計使用6組伺服馬達系統代替舊型離合器操作,可以更精確地構成單板邊緣接合,從而實現完美的連接。直驅馬達的傳動裝置方式,改善鏈條的斷裂連接或造成鬆動。

創新的同步拼接系統設計,以及在拼接過程使用獨特的氣壓缸壓持板面,可促使彎翹的單中板具有良好的拼接品質,最薄可拼0.9mm且無重疊現象

VIDEO:

|

MODEL |

CI-VCB4-IVSS |

CI-VCB5-IVSS |

CI-VCB6-IVSS |

|

|

Length of Knife |

1350 mm |

1650 mm |

1950 mm |

|

|

Working Length |

968 mm to 1270mm |

1220mm to 1620mm |

1650mm to 1,850mm |

|

|

Working Thickness |

0.9 mm to 4.5 mm |

0.9 mm to 4.5 mm |

0.9 mm to 4.5 mm |

|

|

Feeding Speed |

33m-36m/min |

28mm-33m/min |

24m-28m/min |

|

|

No. of glue threads |

5 |

6 |

7 |

|

|

No. of Edge-gluing (Points) |

20 |

26 |

28 |

|

|

No. of detectors |

20 |

22 |

28 |

|

|

No. of over thickness detectors |

2 |

2 |

2 |

|

|

MOTOR |

AC Servomotor System (Details specifications offered by quotation) |

|||

|

Optional Accessories: Air compressor with 3.7kw motor

(required 6kg/cm air pressure. 1200 liters’/min. free air

|

||||

|

MODEL |

CI-VCB7-IVSS |

CI-VCB8-IVSS |

CI-VCB9-IVSS |

|

|

Length of Knife |

2240 mm |

2750 mm |

2750 mm |

|

|

Working Length |

1650mm to 2100mm |

2000mm to 2600mm |

2400mm to 2700mm |

|

|

Working Thickness |

0.9 mm to 4.5 mm |

0.9 mm to 4.5 mm |

0.9 mm to 4.5 mm |

|

|

Feeding Speed |

24m-28m/min |

22m-26m/min |

22m-26m/min |

|

|

No. of glue threads |

8 |

9 |

10 |

|

|

No. of Edge-gluing (Points) |

30 |

36 |

40 |

|

|

No. of detectors |

34 |

40 |

40 |

|

|

No. of over thickness detectors |

2 |

2 |

2 |

|

|

MOTOR |

AC Servomotor System (Details specifications offered by quotation) |

|||

|

Optional Accessories: Air compressor with 3.7kw motor

(required 6kg/cm air pressure. 1200 liters’/min. free air

|

||||