9ft旋切機

UROKO SERIES

Housed in the frame, the cutting feed mechanism can change two series of feeding in a very short time by the operation of clutch.

Control Station

The control panel is places on the platform beside the left time. As the operation is centralized and the machine is semi-automated, the push-button switchs are highly simplified and yet assure quick operation.

Back-up Roll

Mainly used for the 8’ telescopic spindle type, the back-up roll prevents the deflection of log during the cutting operation.

This roll is installed on the pressure bar and has simplified and rationalized mechanism.The operation of each part of the machine is never restricted by this roll.

Steady Rest

Renew Veneer Rotary Lathe In-feeding System

AC Servo Motor:

Stable type high speed motor used instead of belt for driving to make kinfe carrige of cutting set more steady and get a superier quality

採用穩定式高速馬達驅動非皮帶帶動 使刀座轉動更加穩定 品質更優良.

精密進刀螺桿組件:

精密螺桿可使進刀速度穩定,可調整並有效率控制厚度.

Precision screw Assembly:

Precision screw feed speed allows stable, scalable and efficient control of the thickness

Cutting Feed Mechanism

Housed in the frame, the cutting feed mechanism can change two series of feeding in a very short time by the operation of clutch.

Control Station

The control panel is places on the platform beside the left time. As the operation is centralized and the machine is semi-automated, the push-button switchs are highly simplified and yet assure quick operation.

Back-up Roll

Mainly used for the 8’ telescopic spindle type, the back-up roll prevents the deflection of log during the cutting operation.

This roll is installed on the pressure bar and has simplified and rationalized mechanism.The operation of each part of the machine is never restricted by this roll.

Steady Rest

The steady rest is used in the case where the minimum length of log is extremely small and large quantities of such logs are to be processed in the single spindle lathe. Needle roller bearing are used for the spindle to assure high-speed and powerful cutting

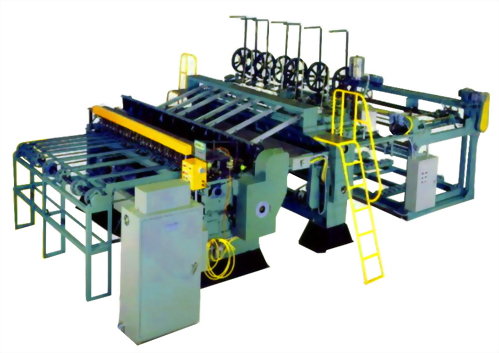

Uroko 9 Feet Veneer Peeling Lathe(Improvement & Overhaul)

MODLE:REB-9

| Max. length of log to be peeled | 2,760m/m |

| Min. length of log to be peeled | 1,800m/m |

| Max. diam. Of log to be peeled | 1,650m/m |

| Diameter of spindle(Large) | 200m/m |

| Diameter of spindle(Small) | 120m/m |

| R.P.M. of main spindle | 0-200 |

| Veneer thickness | 0.5-6.0m/m |

| MOTORS: | |

| For oil pump | 15kw4P-2set |

| For oil pump | 3.7kw6P-2set 0.1kw4P-2set |

| For knife stock quick feed | 7.5kw4P-1set |

| For knife opening adjusting(1/10) | 0.75kw4P-1set |

| For cutting angle adjusting | 2.2kw4P-1set |

| For edge veneer conveyor | 0.75kw6P-1set |

| For compressor | 3.7kw4P-1set |

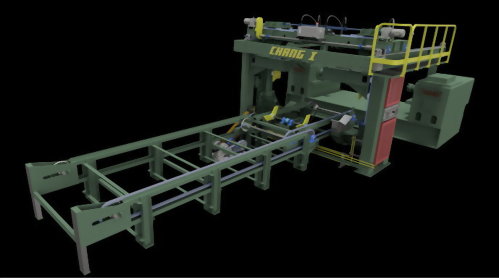

Recondition Raute Veneer Lathe, replace original hydraulic infeed system, recondition to infeed screw(servo system)

Renew Veneer Rotary Lathe In-feeding System

AC Servo Motor:

Stable type high speed motor used instead of belt for driving to make kinfe carrige of cutting set more steady and get a superier quality

採用穩定式高速馬達驅動非皮帶帶動 使刀座轉動更加穩定 品質更優良.

精密進刀螺桿組件:

精密螺桿可使進刀速度穩定,可調整並有效率控制厚度.

Precision screw Assembly:

Precision screw feed speed allows stable, scalable and efficient control of the thickness